Consider this nightmare road scenario:

You are driving along a dark country road late in the evening and a belt suddenly breaks. Your vehicle is inoperable. It’s late, and you fumble to find your phone in hopes that you can reach a roadside service for assistance.

Scenarios like this can happen, especially if you ignore important maintenance items like your vehicle belts. In this month’s blog, we examine the function of your vehicle’s belts, and look at a specific problem you might encounter with a component of the belt system – the belt tensioner.

The Importance of Vehicle Belts

So, what are belts and why are they so important to keeping your vehicle operating safely and effectively?

When you operate your vehicle, it represents a synchronized process of various mechanical functions. Included in this process are your vehicle’s belts. Belts serve an important purpose in providing power to other engine components, or accessories in your vehicle.

The two types of belts you will typically find in your vehicle are:

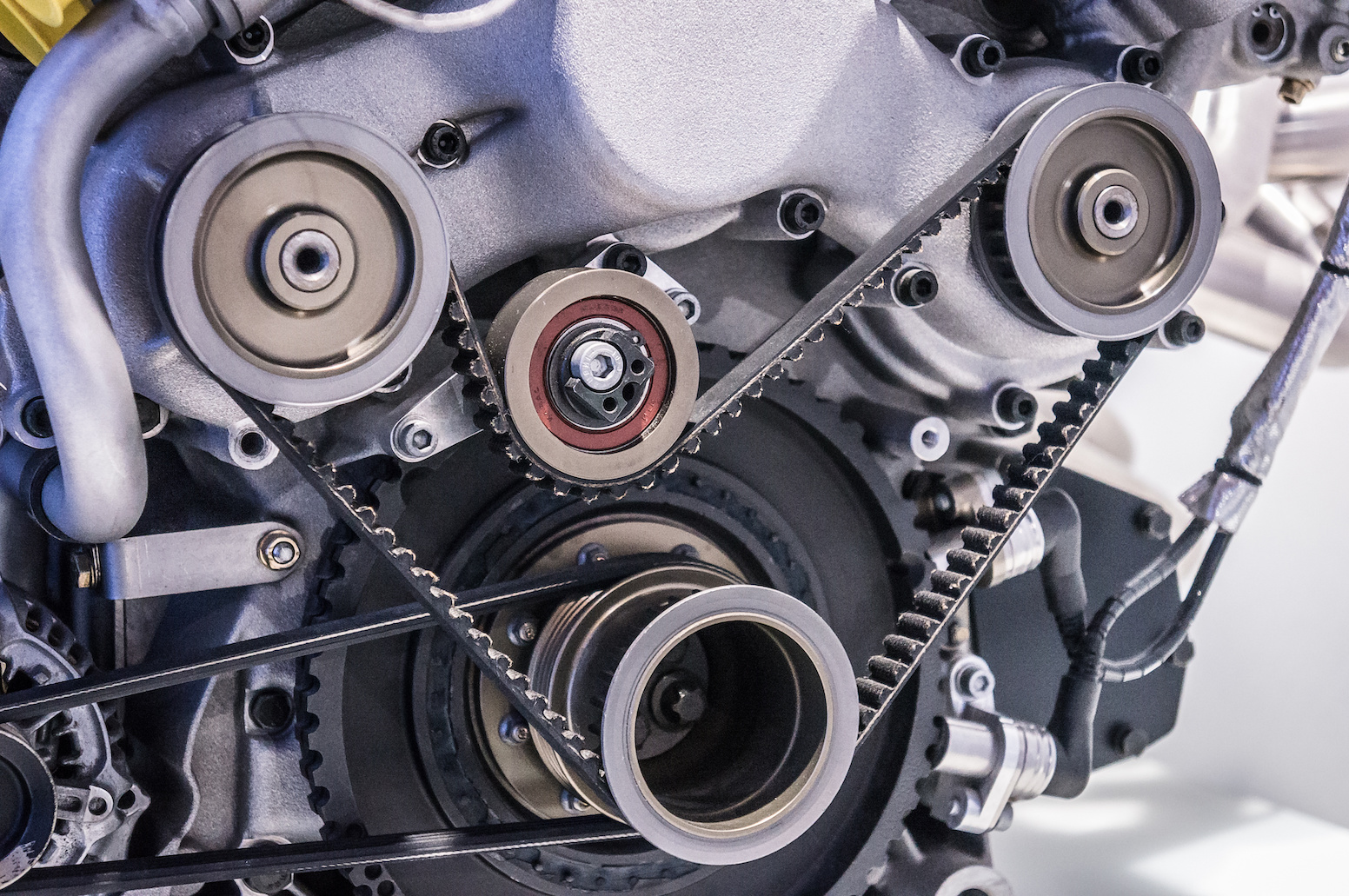

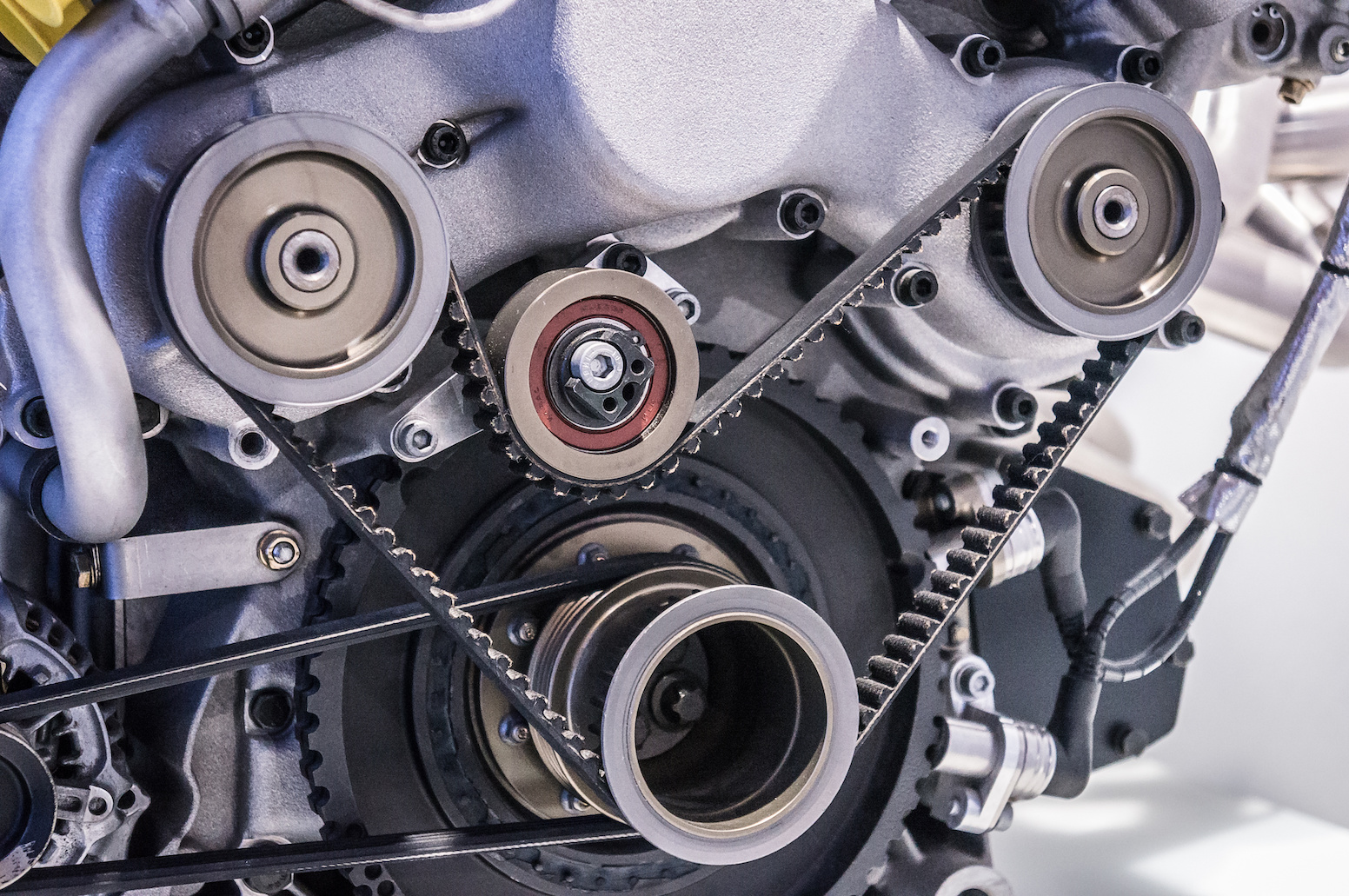

- Drive Belt, or sometimes called the Timing Belt. The drive belt powers the pistons and valves to make the internal combustion process work. This reinforced rubber belt is marked with teeth to ensure a good catch to the parts as it provides power to the pistons and valves.

- Serpentine Belt. The serpentine belt is a long, reinforced rubber belt that powers many functions, including the alternator, power steering, AC compressor, and the water pump. These vehicle accessories need this additional power to operate.

Some vehicles may have what are called v-belts. A v-belt is like the serpentine belt; however, it is smaller and may only power a single accessory. These are found in older vehicles and were used in place of a single belt to eliminate total power failure when the belt broke.

Keeping Belts Working

In simplest terms, belts are hard rubber bands that spin around the inside or outside of the engine to deliver power to other engine components or accessories. Because of the constant movement, belts need to maintain a specific resistance level, or tension, to operate effectively. That’s where the belt tensioner comes into the picture. The belt tensioner is a component of the system that maintains the right resistance of the belts. Belts that are too loose will not function properly, and too tight may break.

The belt tensioner performs its task through a series of pulleys, springs, and the tensioner arm. The pulleys or springs are set for a specific tension, and that enables the belt to continue to operate. As problems develop with the tensioner, this will have a direct impact on the belts.

Problem Signs with Belt Tensioners

If your belt tensioners are heading in the direction of eventual failure from wear and tear, you may be alerted with a few problem signs. The more common ones to look for include:

- Noises: Strange sounds from the engine. When you start the vehicle, you may hear a clicking or other noises as the belt spins.

- Wear: If you can look at your belt, you may find the edges frayed or worn. This is a sign that there may be a problem with the belt tensioner.

- Malfunction: Because your belts power other components and accessories, if you experience malfunctions with them, it might indicate a tensioner issue that has impacted the belt’s ability to perform. This may not always be the case but if you have multiple components not working, it might be a sign there’s an issue that with the tensioner.

If you think that you may have a possible problem with your belts, or the tensioner, contact the service professionals at Colonial Service Station for a complete inspection. We will look over the belt system and provide you with recommendations for any necessary repairs or replacements.